Polyester vs. Polypropylene (Kimdura) Labels: Which One is Right for You?

Posted by Midwest Barcoding Solutions on Mar 14th 2025

If your business relies on durable thermal barcode labels, you’ve probably come across polyester and polypropylene (sometimes called Kimdura®). These plastic-based materials are much stronger than paper labels, making them ideal for harsh environments. But what sets them apart, and which one is the best fit for your needs? Let’s break it down.

What Are They?

Both polyester and polypropylene are types of plastic, but they have distinct properties:

Polyester

Known for its exceptional strength, tear resistance, and ability to withstand extreme temperatures. It is highly durable, making it a top choice for tough industrial applications.

Polypropylene (Kimdura®)

More flexible and generally more cost-effective. Kimdura is a specialized type of polypropylene that offers enhanced resistance to chemicals, moisture, and abrasion, making it well-suited for outdoor and high-moisture environments.

![]()

Appearance: How Do They Look?

- Polyester labels are available in various finishes, including glossy white, matte silver, and clear. For industrial applications, metallic polyester labels with a matte finish are also common.

- Polypropylene (Kimdura®) labels typically have a matte finish but are also available in glossy or clear varieties. Glossy polypropylene is used in applications where ultra-high durability isn't required.

![]()

Temperature Resistance: Which Can Handle Extreme Heat or Cold?

- Polyester labels withstand a wide temperature range, from -40°F to 300°F (-40°C to 149°C), making them ideal for environments with high heat exposure, such as machinery, outdoor equipment, or electronics.

- Polypropylene (Kimdura®) labels perform well in cold environments, withstanding temperatures from -75°F to 200°F (-59°C to 93°C). This makes them particularly useful for freezer storage and cold supply chain applications.

![]()

Durability Against Chemicals, Water, and Weather

- Polyester labels offer superior resistance to tearing, water, and harsh chemicals like oils, solvents, and acids. They also resist UV exposure, meaning they can last three years or more in outdoor conditions without significant degradation.

- Polypropylene (Kimdura®) labels are also resistant to water, chemicals, and abrasion but generally don’t last as long outdoors. They are a great choice for short-term outdoor use (6 months to 1 year) and for applications where moisture resistance is key, such as refrigerated or damp environments.

![]()

Lifespan: Which Lasts Longer?

- Polyester labels are highly durable and maintain their integrity for years, making them ideal for applications where longevity is critical.

- Polypropylene labels are durable but not as long-lasting as polyester, especially in extreme conditions. They are more suited for applications where moderate durability is acceptable.

![]()

Printing & Ribbon Compatibility: What Works Best?

For thermal transfer printing, the right ribbon is crucial for long-lasting print quality:

- Polyester labels require resin ribbons to ensure durability. Resin prints are highly resistant to chemicals, heat, and abrasion, making them perfect for demanding environments.

- Polypropylene (Kimdura®) labels work well with wax-resin ribbons, offering a balance of durability and affordability. However, for added chemical and abrasion resistance, resin ribbons can also be used.

![]()

Cost Considerations: Which Is More Budget-Friendly?

- Polypropylene (Kimdura®) labels are generally more affordable than polyester, making them a cost-effective option for businesses that require high volumes of labels but don’t need extreme durability.

- Polyester labels, while more expensive, provide long-term value by reducing the need for replacements in demanding environments.

![]()

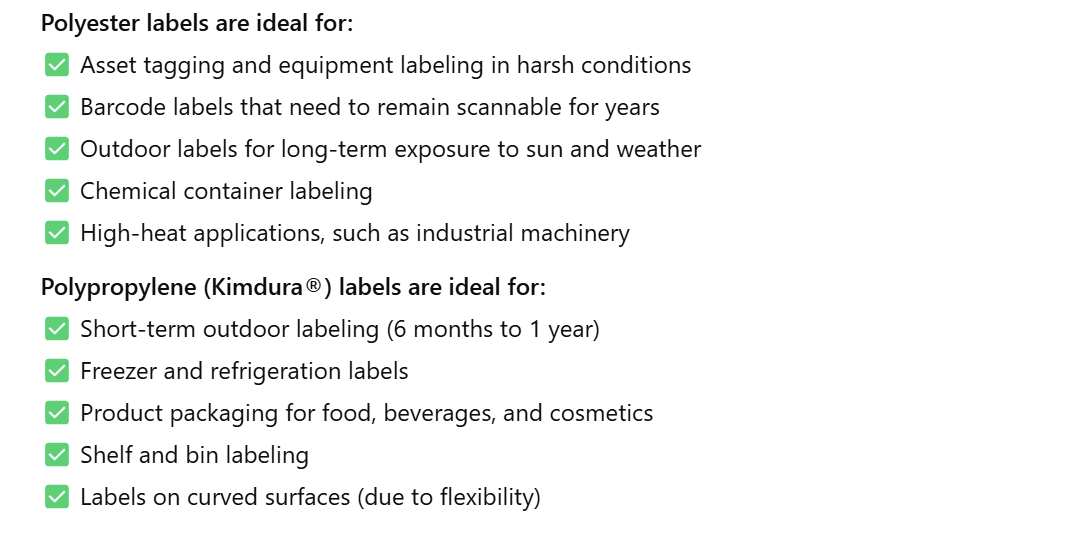

Best Applications: Where Should You Use Them?

![]()

The Importance of a Reliable Label Supplier

Not all labels are created equal. Choosing the right supplier ensures you get high-quality materials and the correct ribbon pairing for your specific application.

Midwest Barcoding Solutions has been a trusted provider of thermal barcode labels for over 30 years. They offer a wide selection of standard and custom labels, as well as barcode scanners, mobile computers, printers, ribbons, and repair services. Known for exceptional customer support and fast shipping, Midwest Barcoding Solutions can help you find the perfect label solution tailored to your business needs.

Final Thoughts: Polyester vs. Polypropylene

| Feature | Polyester | Polypropylene (Kimdura®) |

|---|---|---|

| Durability | Very strong, tear-resistant | Durable but more flexible |

| Temperature Range | -40°F to 300°F (-40°C to 149°C) | -75°F to 200°F (-59°C to 93°C) |

| Chemical Resistance | Excellent | Very good |

| Water Resistance | Excellent | Excellent |

| UV/Outdoor Longevity | 3+ years | 6 months – 1 year |

| Print Durability | Requires resin ribbon (most durable) | Works with wax-resin or resin ribbons |

| Cost | Higher upfront cost but lasts longer | More budget-friendly |

When choosing between polyester and polypropylene (Kimdura®) labels, consider where they’ll be used and how long they need to last. A trusted supplier like Midwest Barcoding Solutions can help you select the right label material for your specific application—ensuring maximum durability and cost efficiency.

Looking for the perfect label solution? Contact Midwest Barcoding Solutions today!

Talk to an Expert